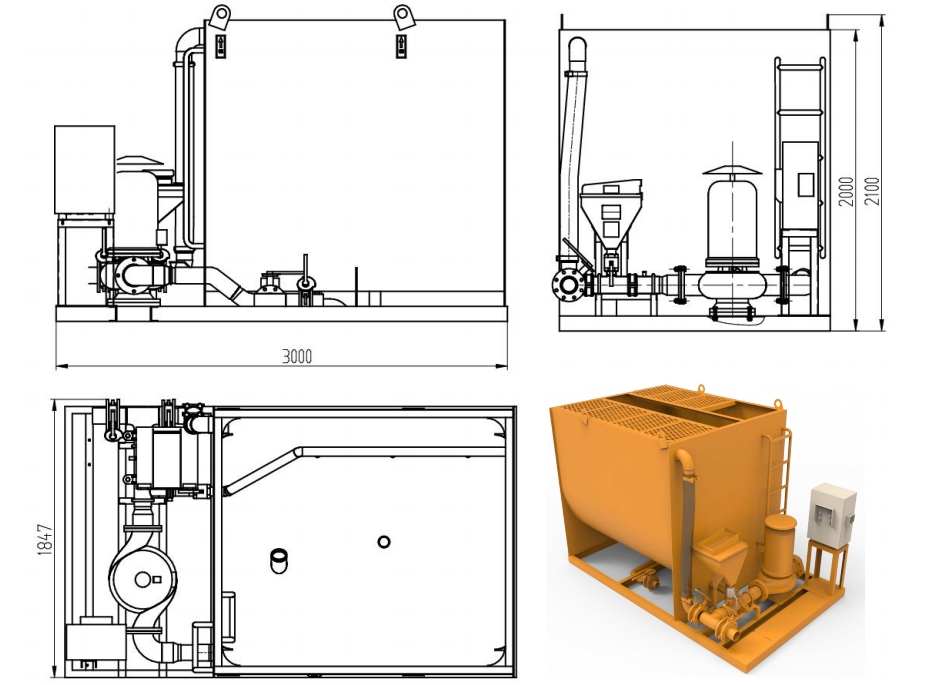

GMME5 Slurry mixer with Capacity 5m³

Product Details:

Specification:

| Parameter | GMME5 |

| Circulation Capacity | 120 m³/h |

| Capacity | 5 m³ |

| Diameter of Outlet | DN100 |

| Total Power | 15 kW |

| Working Dimensions ( L×W×H ) | 3.0×1.8×2.1m |

| Weight | 1550 kg |

Feature:

The mud mixer is designed to prepare and mix slurry used in construction applications such as trenching, bored piles, no-dig piling, and horizontal directional drilling (HDD). The unit comprises a high-speed mixing device, pump unit, pipe assembly, and slurry tank.

Efficient Mixing Performance: Equipped with a high-speed mixing device to ensure quick and uniform slurry preparation.

Integrated Design: Combines mixing, pumping, and storage in one compact unit for easy operation and transport.

High-Quality Pump Unit: Ensures stable slurry circulation and delivery, suitable for various construction needs.

Robust Pipe Assembly: Corrosion-resistant and durable piping system designed for long-term use and minimal maintenance.

Customizable Tank Capacity: Available in different sizes to meet project-specific slurry volume requirements.

User-Friendly Operation: Simple controls and clear layout enhance ease of use and reduce training time.

Advantages:

Precise Slurry Mixing

Ensures consistent slurry density to improve borehole quality and overall construction performance.Enhanced Additive Integration

Fully blends additives with bentonite to maintain optimal colloid content, boosting slurry stability and effectiveness.Rapid Bentonite Hydration

Speeds up the swelling process of bentonite, significantly shortening slurry preparation time.Increased Construction Efficiency

Saves time and labor with faster mixing and reduced manual handling.Reduced Material Waste

Minimizes clumping and improves material utilization—saving 10%–15% bentonite compared to traditional methods.

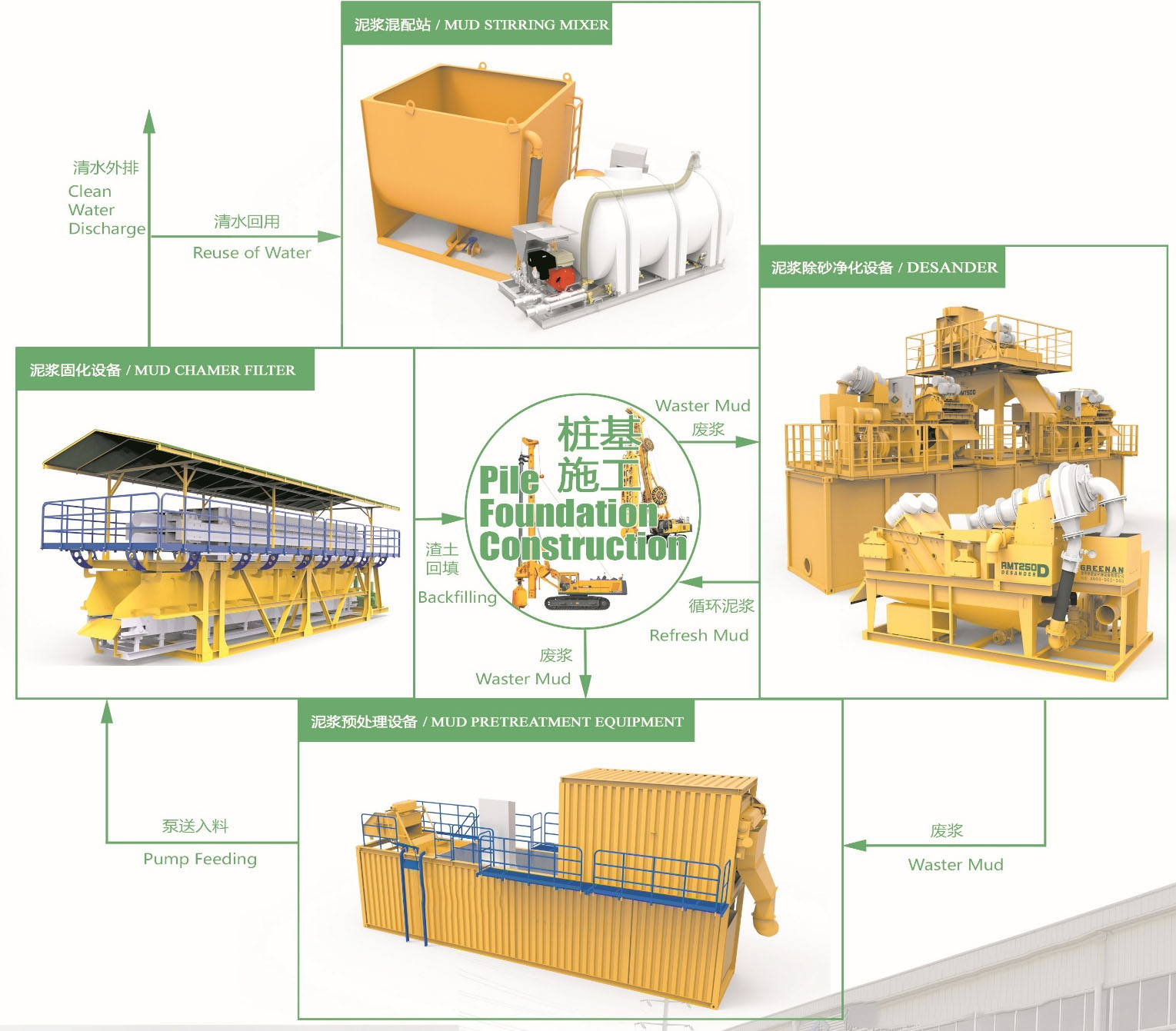

Construction Process: